AirPods Pro 3

I drove quality plan and design validation for AirPods Pro 3 through full product lifecycle.

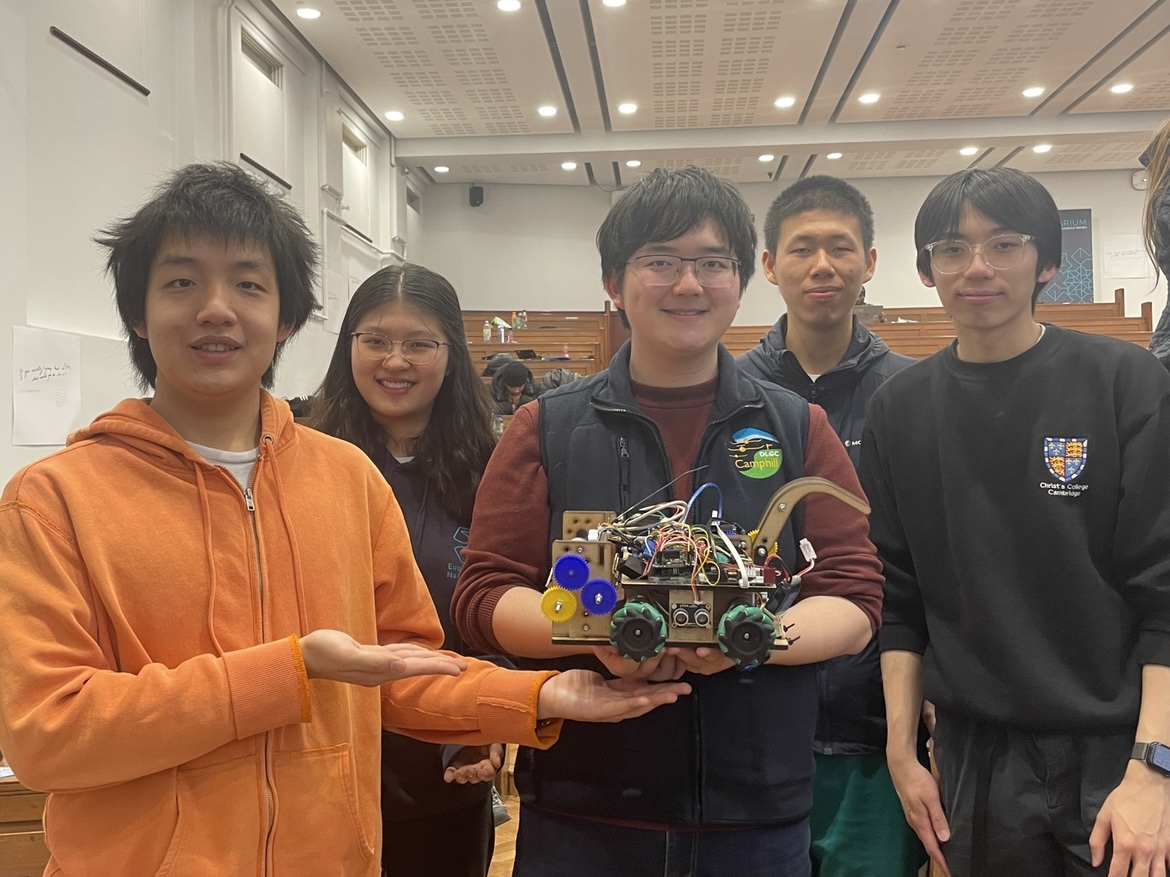

I am an undergraduate student at the University of Cambridge, interested in the field of robotics engineering, with expertise in mechanical design, software implementation, and machine learning. I was a Product Design Engineer Intern@Apple, between June 2024, and July 2025. I was the mechanical design leader for my high school’s FIRST Robotics Team, where I led the development and implementation of diverse mechanical design projects and oversaw the development, testing, and validation of control algorithms. I was an undergraduate researcher at the University of Cambridge’s Bio-Inspired Robotics Lab between June 2023 and Feb 2024.

Beyond my aforementioned experiences, I am passionate about applying machine learning to enhance intelligent robotics systems, particularly by optimizing sensor feedback readings and bridging the gap between mechanics and electrical systems. I’m also interested in creating amazing consumer electronic products that would enhance each life.

I drove quality plan and design validation for AirPods Pro 3 through full product lifecycle.

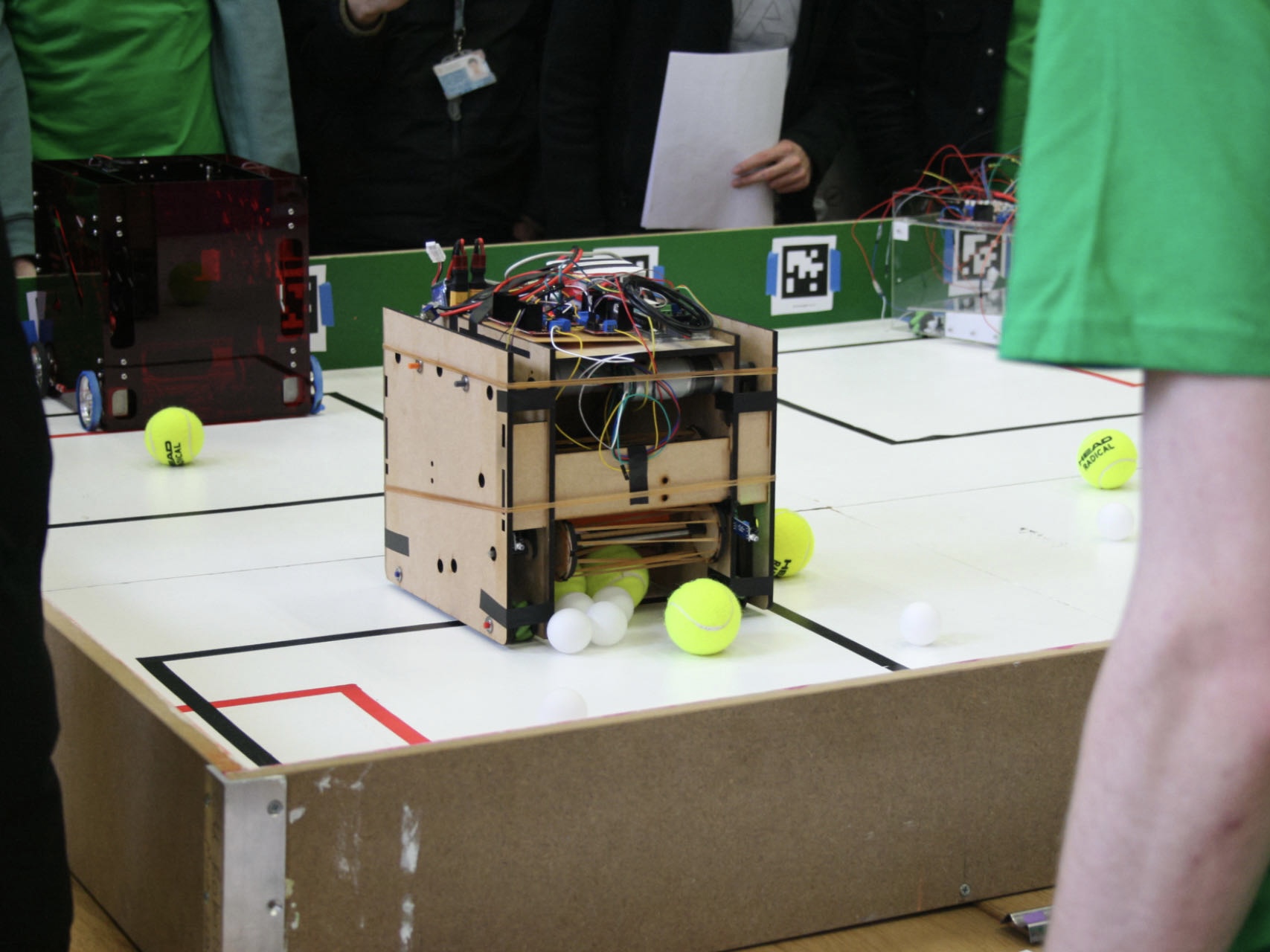

I led a team to compete in the competition, focusing on a sustainable design. I utilized FDM printing and laser-cut MDF, guided by Design for Manufacturability (DFM) and Design for Assembly (DFA), to minimize environmental impact and streamline assembly. Through Solidworks simulations, I and my team perfected the designs, ensuring the robot was both efficient and eco-friendly.

I served as the lead mechanical designer for the Unibots project, specializing in ball intake and maneuvering mechanisms. Additionally, I oversaw the robot's characterization and localization design and implementation.

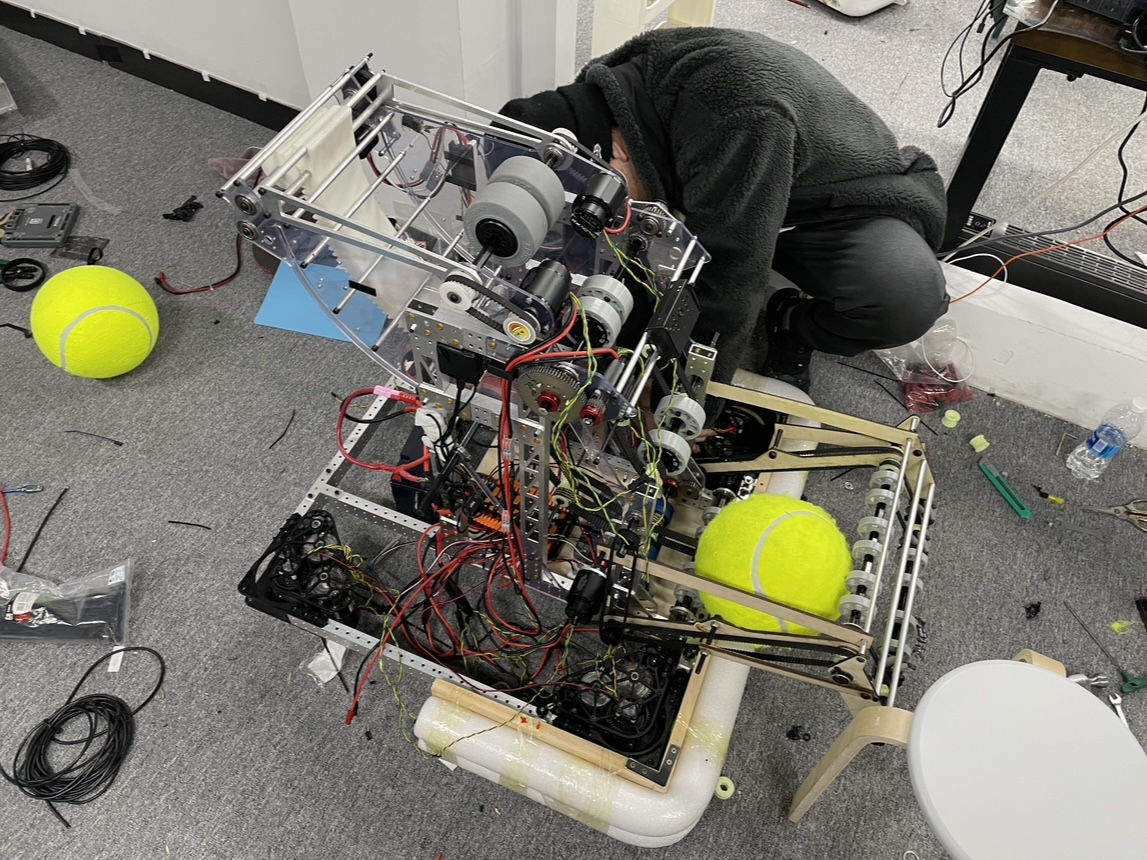

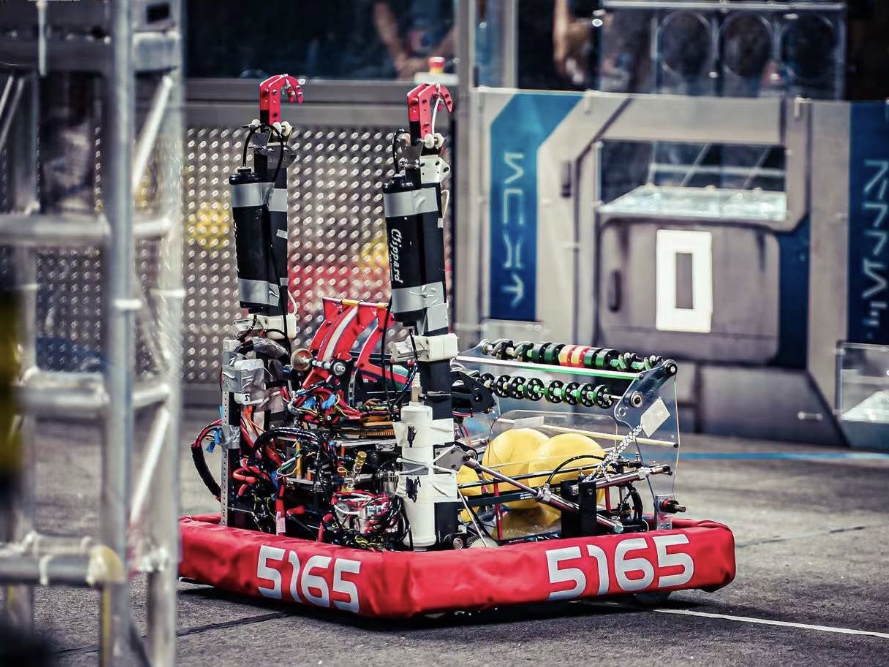

In collaboration with the mechanical design team, I integrated swerve modules into the chassis, designed telescoping arms for the climbing structure, incorporated a pneumatic multi-speed gearbox, and created an adjustable hooded shooter. We also employed vision and point cloud cameras for localization and auto-aiming capabilities.

As the sole robot designer, I employed a conventional pneumatic switchable multi-speed gearbox for the tank drive chassis. I also implemented a serial design to align balls, enhancing shooting speed. Additionally, a vision camera was integrated to estimate the target's distance and direction, automatically adjusting the shooting speed and hooded shooter angle.

Powered by Jekyll and Minimal Light theme.